We have always believed in working closely with the builders to learn on the field and be able to design real solutions.

A path that has made us grow over the years, giving us the opportunity to learn and improve our approach to design.

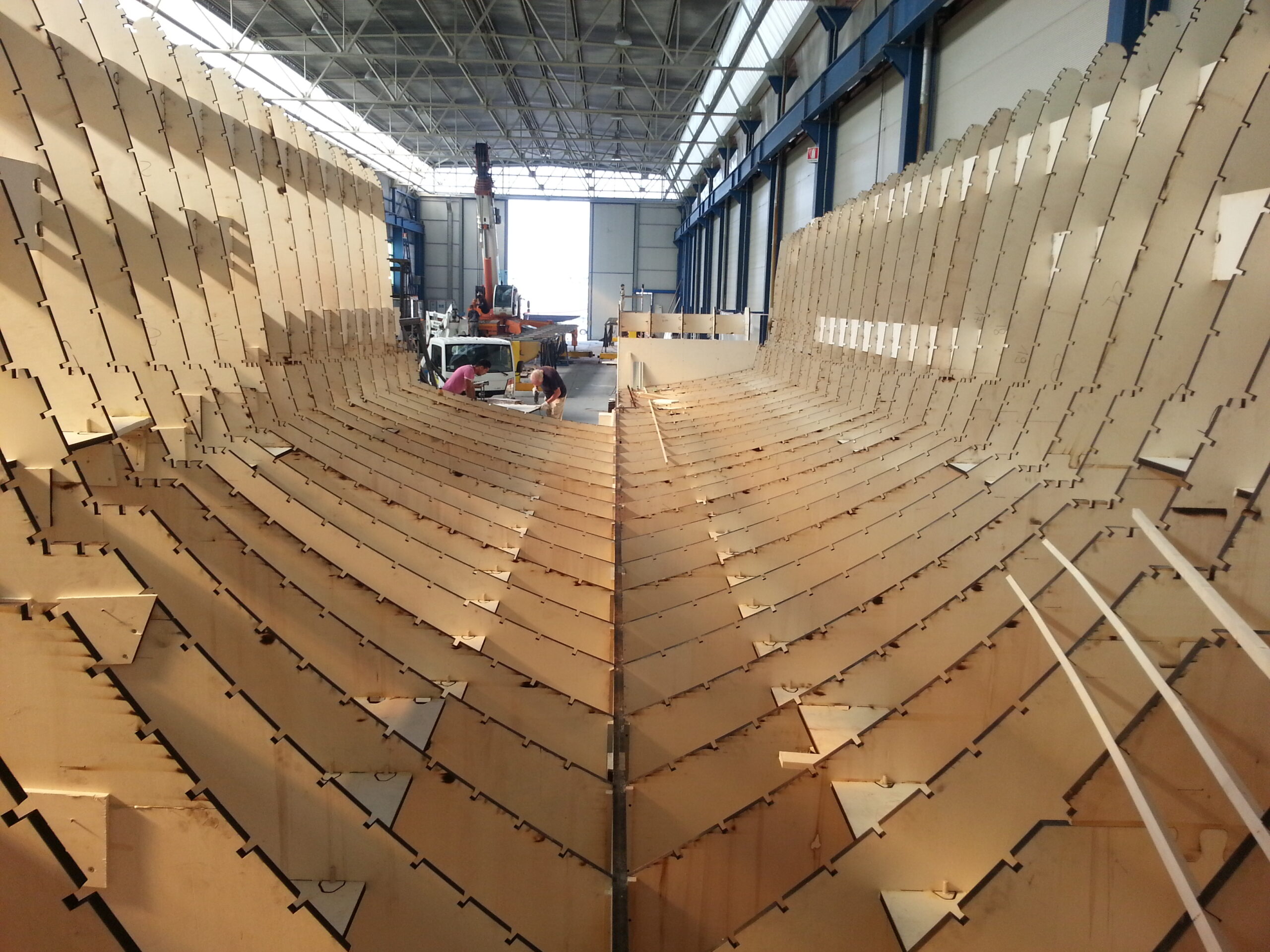

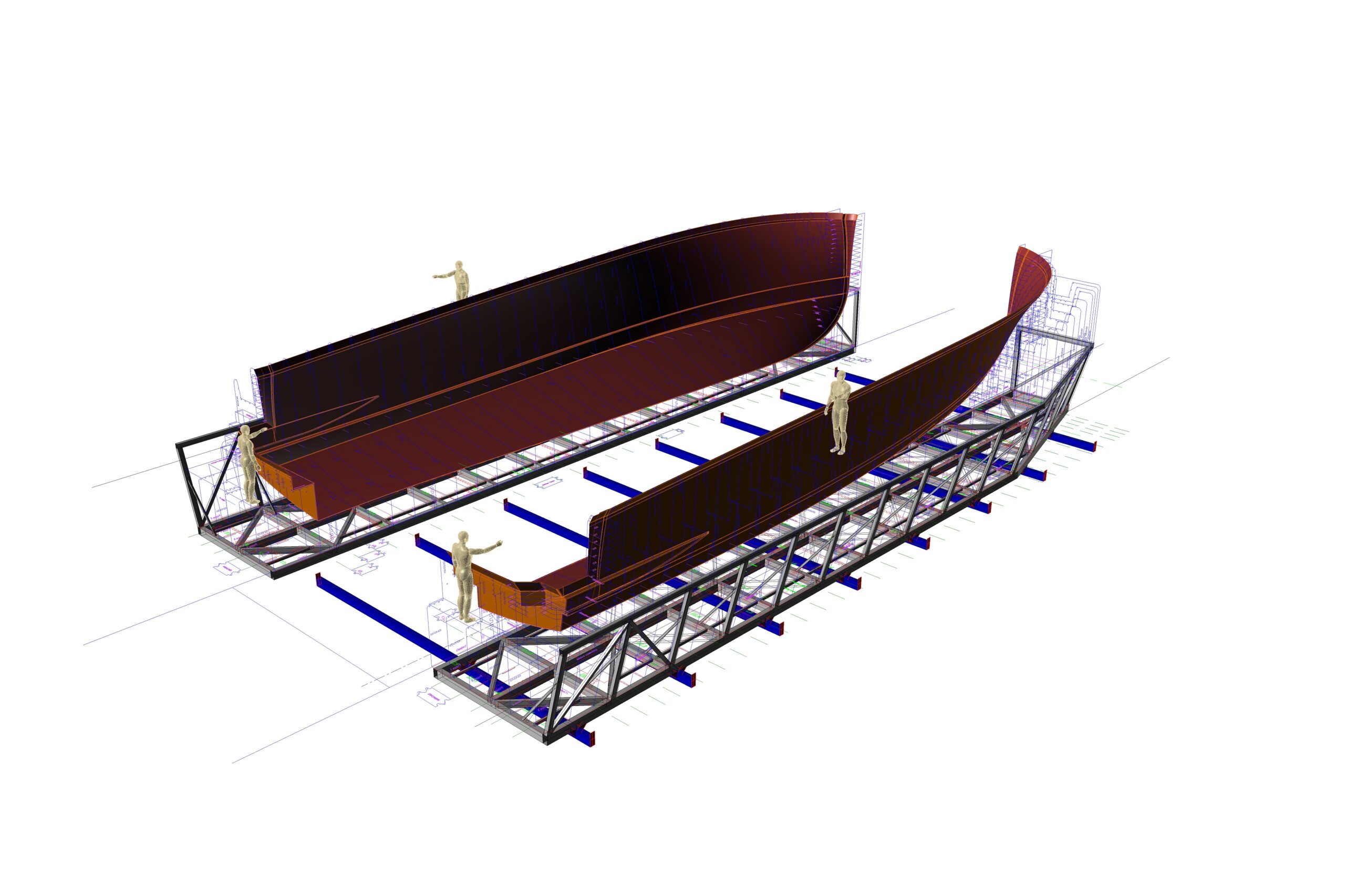

Adragna Yacht Design Studio has great experience in designing boats and also yachts molds; in 2005 we patented a system to speed up the plugs and molds construction.

Laser cut frames assembled on a precut basement with all references as distances between pieces to assembly.

The result was a very fast assembly of plugs and direct female molds with an incredible time saving.

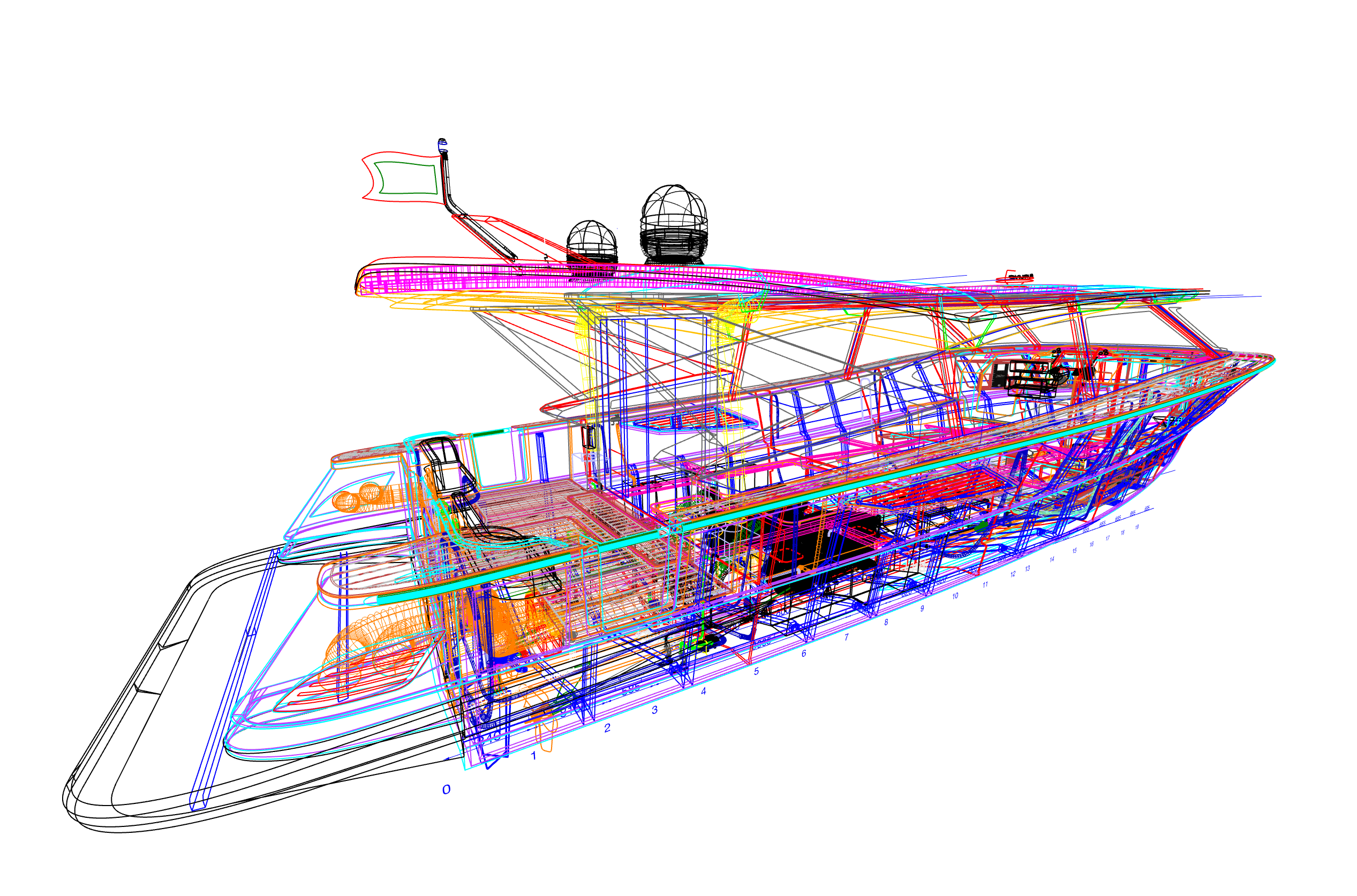

Every particulars on board are studied to be functional at the sea to improve the boating experience.

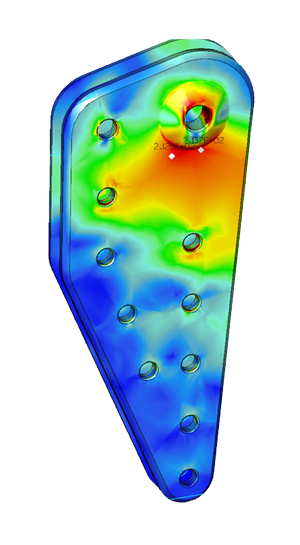

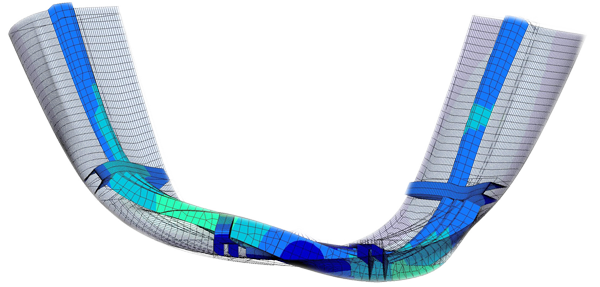

Engineering for us is the basis in the design of our yachts, starting from the design of the hull lines, passing through the compartmentation and on-board systems, ending with the launch with the sea trials.

A 360° full immersion experience to conceive a functional yacht designed to be marine!